Coatings, wood and steel

When it comes to the new Polarstern, various aspects of sustainability were considered. Shipyards vying for the construction tender not only had to meet stringent criteria for environmental management, occupational safety and health, transparently document their supply chain, and confirm their use of certified materials; it was also crucial that they chiefly use sustainable materials to build the ship. This applies e.g. to the wood used for the deck, the interior furnishings, and the large quantities of lacquers, oils and other coatings needed on ships. But one of the largest material items concerns the steel needed for the ship’s hull, no less than 14,000 metric tons. Making that much steel produces massive amounts of carbon dioxide: two tons of CO2 per ton of steel is the standard ratio. Since there is no viable alternative to steel given the ship’s operating areas, the amount used will be kept to a minimum. For example, the shipyard’s modern production facilities will optimally reduce waste. In addition, the plan is to use green electricity for the manufacture and welding of the ship’s individual sections, keeping the carbon footprint as small as possible. Despite these challenges, there is every indication that the original Polarstern’s successor will easily meet and exceed the criteria for the Blue Angel certification for environmentally friendly ship design.

Quiet and clean

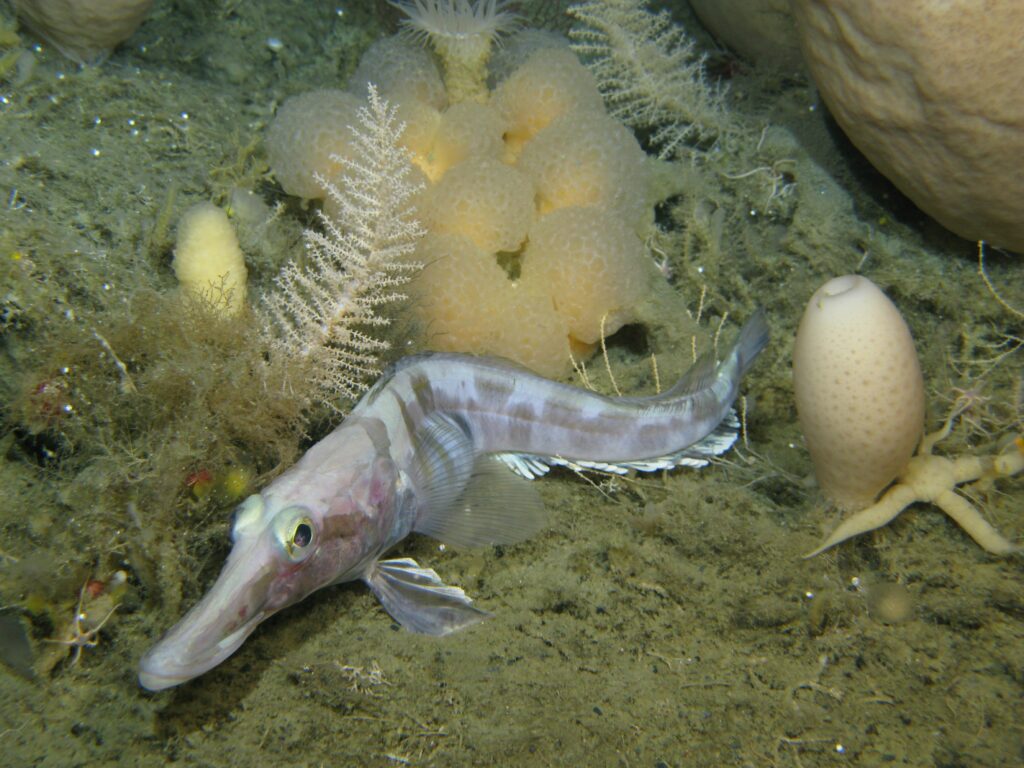

On her research cruises, the new Polarstern will frequently be underway in fragile and largely untouched areas – where the goal is to leave as small a footprint as possible. Accordingly, the new research icebreaker has been designed to operate with minimum environmental impact. That’s possible thanks in part to modern wastewater treatment systems referred to as membrane ultra-filtration systems, which remove nearly all undesired elements, like microplastic but also nutrients, from wastewater. In addition, the hydraulic oils used on deck will be biodegradable. The hull will be sheathed in an ultrahard coating that remains virtually unscathed by contact with ice. This represents a major advancement compared to the situation on most other ships, where paint particles constantly flake off the hull, releasing biocides from their antifouling components – chemicals designed to prevent the accumulation of algae, bivalves and other marine organisms – into the water. To avoid these “stowaways” on the new Polarstern, the ship employs a targeted, high-tech system. In addition to regularly scheduled hull cleaning, the differences in water temperatures when underway from one research area to the other also help in this regard – since very few organisms can withstand these extreme temperature changes. In addition to pollutants, the noise produced by ships can be a problem for marine fauna – e.g. by disrupting the natural behaviour of fish or communication between whales. Consequently, the new Polarstern will run extremely quietly, primarily even keeping below the underwater noise limits set by the International Council for the Exploration of the Sea (ICES). Adhering to these limits is voluntary, and the new Polarstern will be the first of her kind to do so.

Clearing the way

The new Polarstern will be as accessible as possible, chiefly in the interest of those with physical disabilities. At the same time, this will facilitate the scientific work done on board. After all, on research icebreakers, heavy equipment and cargo containers have to be moved on a daily basis – and every unnecessary threshold and tight corridor makes it more difficult. Narrow staircases and doors that can’t open and close at the push of a button can quickly become obstacles. Considering such aspects is not yet commonplace in shipping, except on ocean liners. But when it comes to the design of the new Polarstern, many aspects were reconsidered from the ground up.

Another major issue: ensuring people can find their way about the ship as easily as possible. For the ship’s crew, this might not be a problem – but the goal is for guests and expedition participants on board for the first time to also manage. In this regard, solutions like raised tactile markings on the handrails and assigning a different colour to each deck can help. They can also be particularly valuable in emergencies, saving precious time.